Abstract

Peanuts commonly known as groundnuts, monkey nut or goober depending on the location is a representative legume crop in nuts. Shelling of groundnut pods manually is characterized by high kernel breakages, low shelling efficiencies and it is labor intensive. These results to low income for farmers. To minimize the damage rate, reduce man hours and increase productivity, this study examined the physical and mechanical properties to develop a processing machine. The geometric characteristics of the nuts in their pods were 37~42 mm in length, and 14~17 mm in width. The peanut seeds had dimensions in the range of 17~22 mm long and 7.9~9.5 mm wide. This allows a 10 mm gap between the screening plates to prevent the removed pods from passing through. Further mechanical analyses indicated that rubber materials were suitable to ensure the final quality of the peanut seeds. Furthermore, it is possible to adjust the rotational speed of the drum used for cracking the nuts to less than 200 rpm. The performance assessment showed that at a drum rotation speed of 170~200 rpm, the peanut seeds damage rate was between 0.8% and 2.0%. The capacity was 450 kg per hour. In this study, an efficient automatic peanuts shell removal machine was developed.

Figures & Tables

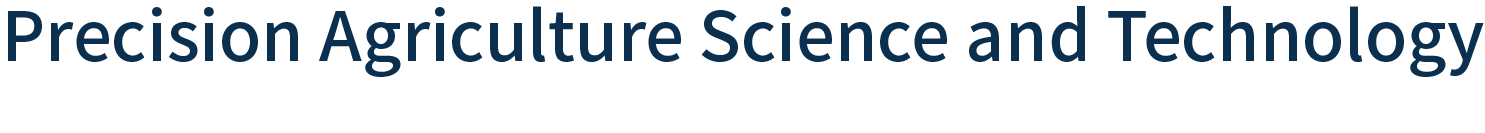

Fig. 1. Length of shelled peanut (A), Camscope to measure the diameters of the peanut (B), Length of inner peanut shell (C), Width of inner peanut shell (D).